When Vehicles Appear to Function or Perform in Unexpected Ways

As an accident reconstructionist and a mechanical engineer that also has electrical engineer training and experience, I have often been asked to examine a vehicle that has been involved in a collision to determine if its function or performance was different than the way a driver indicates it was operated. The implication is that the vehicle malfunctioned in a way that resulted in a collision through no fault of the driver. From memory, the more common instances I have investigated include the following situations:

- “My vehicle was accelerating even though I was pressing the brake with all my strength.” (Unintended Acceleration)

- “My vehicle suddenly steered into the path of the oncoming car.” (Unintended Steering)

- “I was pressing my brake pedal, but the vehicle was not slowing down.” (Brake Malfunction)

- And most recently, “My collision mitigation system did not detect the object in the roadway.” (Advanced Driver Assistance System Malfunction)

In light of technical studies and recalls, some of the complaints above are not without merit. In the case of Unintended Acceleration, Toyota Motor Corp. has been faced with lawsuits claiming "tin whisker" formation that resulted in electronic throttle control system malfunctions. A 2011 NASA report, however, conducted for NHTSA from a 10-month study indicated there was no evidence of electronic flaws. "There is no electronic-based cause for unintended high-speed acceleration in Toyotas" (U.S. Transportation Secretary Ray LaHood). Unintended acceleration is instead attributed to mechanical flaws, such as sticking accelerator pedals, floor mats that jammed the pedals, or driver error. This finding has resulted in these known recalls:

- Toyota's series of recalls began in Sept 2009 with an announcement that 3.8 million vehicles were being recalled because of a defect that may cause floor mats to jam down the accelerator pedal.

- In January 2010, the company recalled 2.3 million vehicles to fix sticking gas pedals.

- In February 2010, another 2.17 million vehicles in the U.S. were recalled for carpet and floor-mat flaws that could jam gas pedals.

I’m sure that more recalls of a mechanical, rather than electrical nature have been forthcoming since that time that involve Toyota in addition to the other automotive manufacturers.

My own experiences in these cases have involved the following findings:

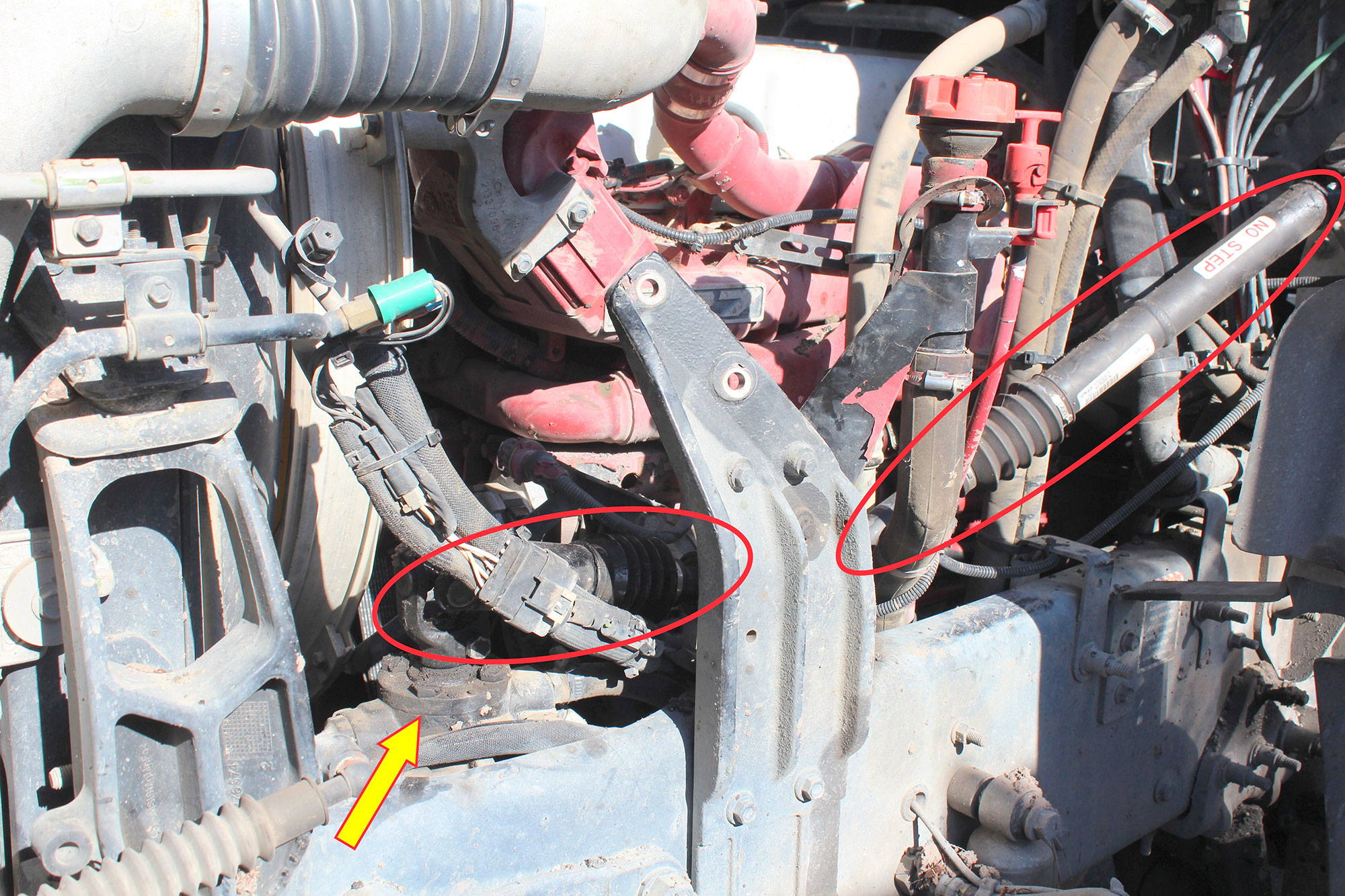

For unintended accelerations, the brake and accelerator linkages are examined to eliminate any damage or defect that would result in hanging or binding. In the absence of such, the vehicle’s airbag, engine, or powertrain control modules can also be downloaded. Although crash data recorder (CDR) reports do not indicate where an input originated (electronics, mechanical, or driver), under conditions wherein the driver insists "I was pressing the brake as hard as I could" I have performed downloads and shown that just the accelerator was pressed, instead of the brake, signifying driver input error.

In the case of Unintended Steering, again, the steering mechanism can be examined and oftentimes tested to detect mechanical deficiencies. In the absence of these, electronic downloads are performed to determine if the steering inputs were consistent with the motion of the vehicle in the collision. Absent any tire slippage conditions, data inconsistent with the vehicle’s motion could indicate a control problem. My experience in one case to date, however, has been to find that, despite the vehicle manufacturer’s warnings to the contrary, the driver had been using the vehicle’s Lane-Centering Steering (LCS) system in a hands-off attitude, as indicated by a system-disengage signaled prior to the collision. It was determined that the vehicle user’s manual informs that the LCS is not a full automation system and is programmed to disengage after a certain time if it detects no steering inputs from the driver. A very prominent warning is included in the user’s manual to this effect and state’s that the driver is to maintain full control of the vehicle’s steering at all times for this purpose, whether the LCS system is engaged or not. The collision cause, in this case, was attributed to driver misuse of the LCS system.

In the case of brake malfunction, the braking system can be examined and tested. Experience has shown, however, that even though the braking system functions, its performance can be degraded due to defects in repairs, wear-and-tear of the system components (lack of maintenance), or driver misuse of the braking system as sometimes takes place in hilly terrain, where the brakes are ridden for prolonged periods on downhill slopes, resulting in overheating and brake fade, as indicated by glazed brake pads. These findings often require wheel removal and brake disassembly such that the friction surfaces of the brake pads can be examined and documented. Examinations to this extent will require the assistance of a mobile mechanical repair service, especially in the case of large commercial vehicles.

Finally, in the case of apparent Advanced Driver Assistance System (ADAS) malfunctions it cannot be emphasized enough that ADAS, which includes collision mitigation, although advanced, are not yet sophisticated enough to be considered or utilized as a full automation system. For instance, collision mitigation sensing systems function well to detect moving objects but tend to ignore stationary objects that it detects in or near a roadway. This is a known shortcoming and is the reason these systems are classified as Level 2, Partial Automation instead of Level 5, full automation autonomous driving systems. It is also the reason manufacturers warn owners not to use such devices as you would a full automation system. My own experience has included at least two collisions involving driver misuse of an ADAS system by operating it in a head-down, hands-off attitude, wherein the vehicle eventually failed to identify and avoid a construction object or vehicle up ahead.

About the Author

G. Wayne Maltry, AMT, BSAE, MSME, PE is a consulting engineer with our Columbia, SC office. Mr. Maltry provides consulting services in the following areas: fracture and failure analysis, including finite element analysis; aircraft crash and vehicle collision investigation and reconstruction; origin and cause of air and land vehicle, structure and equipment fires; machinery scope of damages; assessment of appliances, machinery, vehicles and equipment (including HVAC); evaluation and analysis of process equipment, plumbing and piping; industrial accident analysis; and lightning damage assessment. You may contact Wayne for your forensic engineering needs at wmaltry@edtengineers.com or (803) 791-8800.

Learn about how EDT Forensic Engineering & Consulting approaches cause of damage, and forensic engineering by assigning a file today.