Thermal Effects In Piping Systems

Thermal Effects In Piping Systems

Have you ever turned on the hot water faucet and after a short period of time, heard creaking noises coming from inside the walls or below the floor? While such noises could be unwelcome guests, such as rodents or space aliens, chances are, the noises are being generated by thermal-related pipe movement. While such noises may be a nuisance, thermal-related pipe movement can cause pipe fractures and coupling separation, resulting in property damage. Understanding how temperature change affects a pipe material is necessary in determining the cause for a pipe system failure. Pipes, regardless of which material it is made of, will experience length change with variations of temperature. Plastic pipe materials will expand, or contract 3 to 10 times more as compared to metal pipe materials. The amount of expansion or contraction is dependent upon the material’s coefficient of linear thermal expansion, the length of the pipe section and the temperature change.

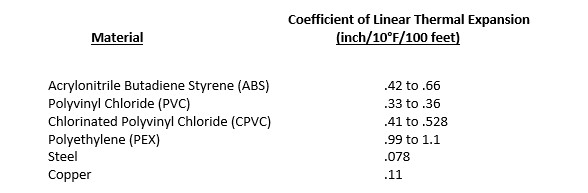

The coefficients of linear thermal expansion for common pipe materials are provided in the table below. The number represents the amount of expansion or contraction in inches per 10° Fahrenheit (F) of temperature change, per 100 feet of pipe.

For example, a 100-foot section of PEX piping experiencing 50°F temperature variation will increase or decrease in length by about 5 ½ inches.

In most residential or other short pipe applications, the change in pipe length is inconsequential other than maybe the sounds you recall hearing since offsets and changes in directions will allow for this pipe movement without causing damage to the pipe itself. However, where pipe lengths are long and straight, and when a significant temperature variation is possible, such as chilled water or heating water applications and many industrial applications, provisions must be included in the pipe design for pipe movement by installing regular expansion loops or expansion fittings. Failure to plan for expansion and contraction of long, straight pipe applications where significant temperature changes can occur, may result in physical pipe damage by deflection leading to pipe breakage or severe contraction leading to pipe/fitting separation. Engineering evaluation of the service conditions, the pipe installation and determining any unique circumstances for a particular situation is necessary to determine if thermally induced forces were involved with a piping system failure.

About the Author

D. Jeff Jaco III, M.E., P.E. is a District Engineering Manager and Consulting Engineer in our Columbia, SC Office. Mr. Jaco provides consultation in the areas of production process improvements and fire protection system evaluations including accidents in commercial, industrial, and residential settings; mechanical equipment damage assessment and repair and replacement cost estimates; and project estimating and scheduling. Furthermore, he performs engineering analysis and investigation of fire protection systems, boilers, plumbing and piping systems, HVAC systems, and gas systems. You may contact him for your forensic engineering needs at djjaco@edtengineers.com or (803) 791-8800.

Learn about how EDT Forensic Engineering & Consulting approaches scope of damage, and forensic engineering by assigning a file today.