Condensate Drainage

To understand proper condensate removal, it is first important to have a working definition of the term condensate in the context of Heating, Ventilation, and Air Conditioning (HVAC). Most HVAC systems contain a form of refrigeration cycle which uses mechanical work acting on a fluid (in most cases refrigerant) to provide cool, dry air to livable spaces. During this process, condensate is generated by what is best described as, “wringing out the water,” from the occupied/conditioned space. A helpful illustration is to think of the air within the conditioned space as a giant, saturated, wet towel. The HVAC system squeezes the water out of this towel.

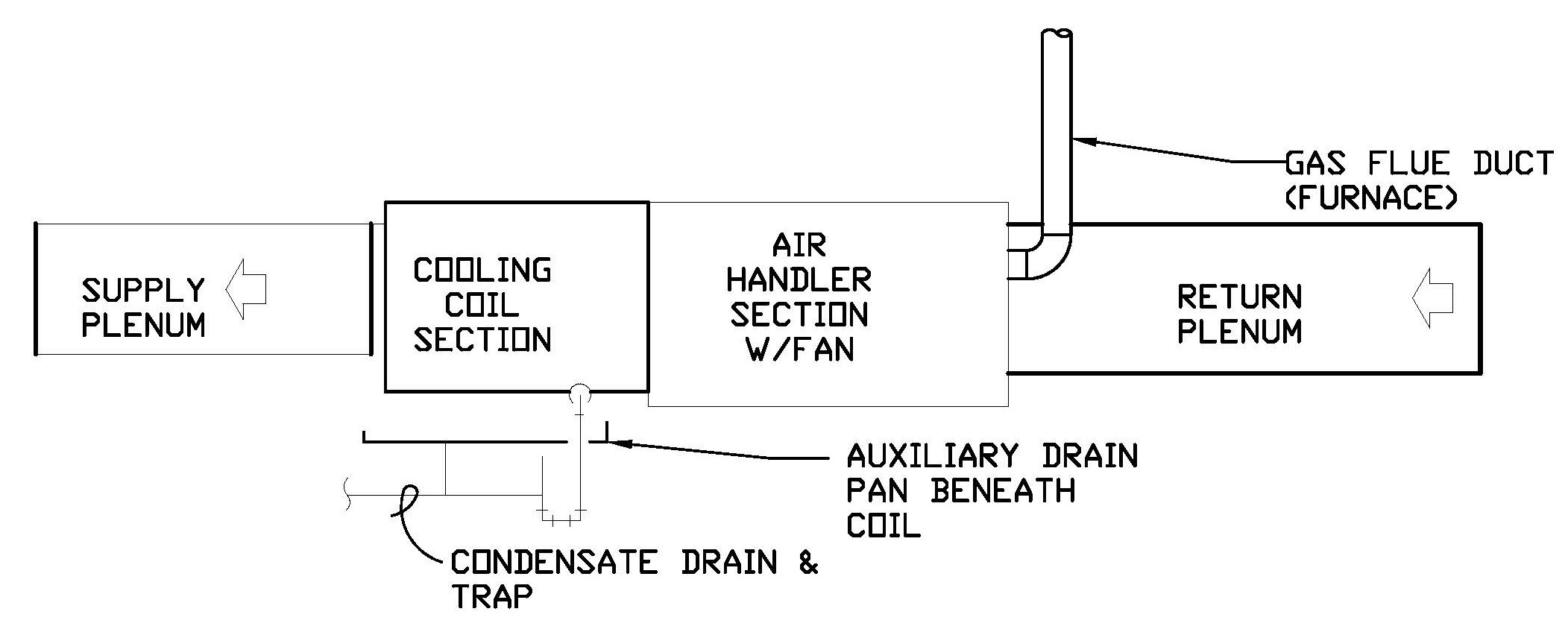

In the case of the residential HVAC system, the condensate removed from the air falls to a drain pan within what is known as the air handling unit. The air handling unit (sometimes furnace) is the indoor portion of a split system and is often located in an attic space or within a basement. Contained within the air handling unit is the coil which accumulates the condensate and it is then disposed of as water in liquid form. The drawing detail below identifies the main components of the air handling unit:

The conveyance and/or disposal of the water from the air handling unit is often a point of failure due to improper installation, lack of maintenance, or exposure to freezing temperatures. Some key points are identified below from the International Residential Code to address installation defects:

- Condensate from all cooling coils or evaporators shall be conveyed from the drain pan outlet to an approved place of disposal.

- It is important to consult local Authority Having Jurisdiction (AHJ) regarding approved disposal locations. Different municipalities may require condensate be disposed of to the sanitary sewer, while others may require disposal to building exterior or storm drainage piping. Some AHJ may even require the use of additional equipment to neutralize certain elements/compounds prior to disposing of the condensate.

- It is important to consult local Authority Having Jurisdiction (AHJ) regarding approved disposal locations. Different municipalities may require condensate be disposed of to the sanitary sewer, while others may require disposal to building exterior or storm drainage piping. Some AHJ may even require the use of additional equipment to neutralize certain elements/compounds prior to disposing of the condensate.

- Horizontal slope must be no less than 1/8-unit vertical in 12 units horizontal.

- Many homeowners experience an unintended water discharge from an air handling unit located in an attic space because the installing contractor did not provide adequate “fall” to the condensate drain piping to permit gravity drainage. This is considered a defect in installation.

- Many homeowners experience an unintended water discharge from an air handling unit located in an attic space because the installing contractor did not provide adequate “fall” to the condensate drain piping to permit gravity drainage. This is considered a defect in installation.

- Condensate shall not discharge to a street, alley, or other areas where it would cause a nuisance.

- Some installations discharge condensate to areas where there may be pedestrian foot traffic. If condensate is discharged to a walkway, it may create a slipping hazard.

P-trap installation can be another source of improper installation. P-traps for use in HVAC applications vary in design, however, the correct trap depends on both the air handling unit’s components as well as the air distribution system (ductwork). The p-trap must always contain the required amount of water to prevent contaminants from entering the HVAC system. In many residential applications, the duct system may have many bends, transitions, or flex-connections where the supply fan of the air handling unit must overcome the added pressure. If the static pressure of the duct system is high, the water-seal of the p-trap may be “pushed” out, allowing contaminants to enter the duct system. Consult with the equipment manufacturer’s data to ensure the proper drain piping and p-trap is used for the system.

A third and common source of improper installation can be found in the secondary (emergency) drainage system. A secondary drainage system is required where the threat of an overflow may damage building components and is often accomplished by a “secondary drain pan” installed under the air handling unit. The secondary drainage system must provide a method, a moisture-sensing switch is typical, to shut down power to the air handling unit, in the event moisture is detected. Many secondary drainage defects include moisture sensing switch faults, improper secondary drain pan piping, or in some instances, no secondary drain pan may be installed at all.

With the increased popularity of high-efficiency equipment, it is important to be aware that these systems can produce condensate year-round, including during the winter months. Installation contractors may plumb the condensate drain to discharge to the outside, as is their usual practice. However, in the case of a high-efficiency furnace, condensate can form in the exhaust gases when the unit is in heating mode. The condensate will then drain to the outside where it is exposed to freezing temperatures, resulting in a backup. Safety switches within the air handling unit are intended to shut the unit off when the condensate backs up. This scenario also applies to the high-efficiency water heaters and the increased popularity of instantaneous water heaters.

Proper maintenance will aid in preventing drainage system failures. Typical maintenance for a condensate drainage system consists of a yearly inspection and in some cases, detergent cleaning of the system. Cleaning is required due to the occasional build-up of debris and material which can accumulate within the drains.

In closing, the conveyance and/or disposal of the water from the air handling unit is often a point of failure related to improper installation, lack of maintenance, or exposure to freezing temperatures. Correct installation, as well as proper maintenance, will address many potential issues.