Transformer Failure: Frequency and Causes

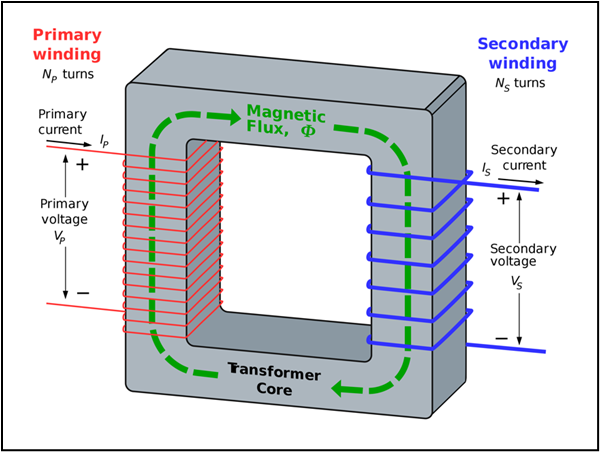

Transformers are among the most reliable and robust elements in the electric utility system. A transformer is basically two sets of wires (the windings) wrapped around a steel or iron core (see schematic in Figure 1). The windings and the core are immersed in oil and enclosed in a steel tank (typical for outdoor power transformers, which will be the focus of this article). The essential core (no pun intended) of the transformer has no moving parts (large power transformers may include cooling fans, oil pumps, and load tap changers).

William Stanley, working for Westinghouse, built the first reliable commercial transformer in 1886. On the robustness of the transformer, he wrote:

"I have a very personal affection for a transformer." "It is such a complete and simple solution for a difficult problem. It so puts to shame all mechanical attempts at regulation. It handles with such ease, certainty, and economy vast loads of energy that are instantly given to or taken from it. It is so reliable, strong, and certain."[1]

It is not unknown in the electric utility industry to see a transformer in service for 50 years or more. However, anyone with experience in electrical power transmission and distribution has seen transformer failures. Given that transformers are so robust and reliable, owners and insurers are often surprised when a transformer fails, but we all know nothing lasts forever. This raises the relevant questions: what is a reasonable expectation for transformer life and what is the probability of a transformer loss?

A frequently cited number in the technical literature on transformer life expectancy from IEEE Standard 493, is 0.0041 failures per year for liquid-filled transformers. This may seem to imply that one could expect a single transformer to fail at the rate of 1/0.0041 or once every 243.9 years. It is well known that transformers do not last for 200+ years. This number is intended to give a probability of failure of any given unit in a year and can be used to predict the number of expected failures in a fleet for a given time period. For example, EDT recently investigated a loss at a 100 MW Photovoltaic solar farm. The installation included 47 oil-filled transformers. Based on IEEE Standard 493 and an assumed 20-year life of the farm it would be expected that there would be about 4 transformer failures over the life of the project as calculated below.

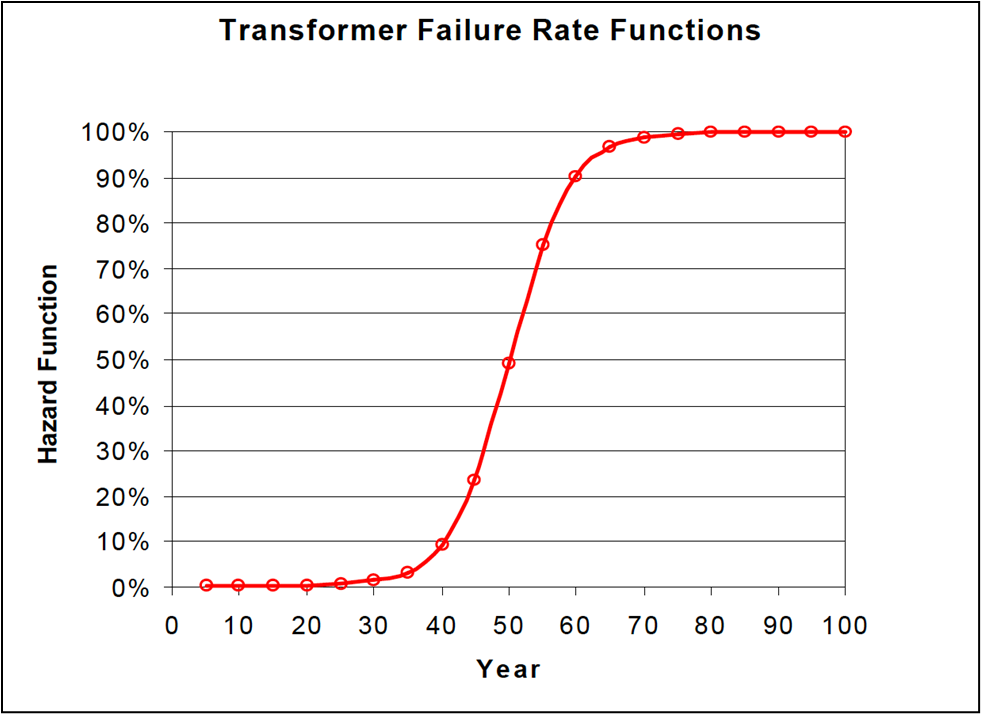

This approach to calculating expected loss based on failure rates does not take into account the age of the transformers. Work done by William Bartley at Hartford Steam Boiler showed that the risk of failure rises with age and that at 50 years of transformer life the risk of failure is about 50%.[2] Data developed by Bartley yielded the curve shown in Figure 2.

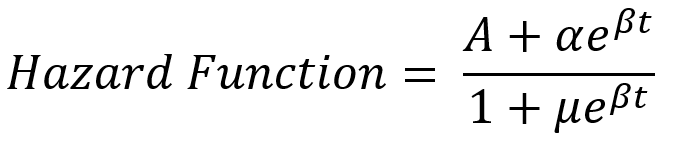

The curve in Figure 2 is derived from the equation shown below. The hazard function is based on work by W. Perks in the 1930s on human mortality for actuary tables.

In the hazard function the “A” term accounts for random events like lightning strikes, vandalism, and collisions, “t” is time in years; the other terms, a, b, and m, are constants that account for age-related failures.

Notice in Figure 2 that for transformers up to 40 years old the hazard function (which can be understood as the probability of failure) is less than 10 percent). So, insurers and adjusters are apparently justified when they are surprised when a transformer fails in the early stages of life. This then suggests the obvious question: why do transformers fail and what is the root cause? After all, determining the root cause of losses is what forensic engineering is all about.

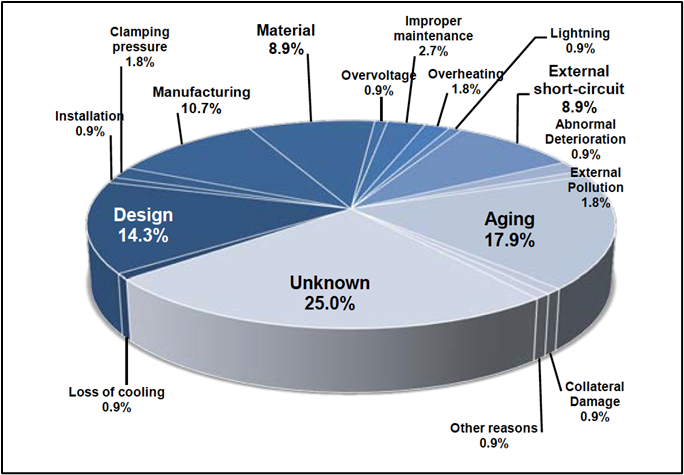

A review of 112 transformer failures in Germany, Austria, Switzerland, and the Netherlands showed the distribution of failure cause shown in Figure 3.[3]

The following is a discussion of the causes of failures shown in Figure 3.

Unknown 25.0% - It is an unfortunate reality of forensic engineering that it is sometimes impractical or even impossible to determine the cause of some losses. When transformers fail enormous quantities of energy are released often sufficient to vaporize the copper (or aluminum) windings and sections of steel cores and to ignite the insulating oil. It is not uncommon for the site of the failure to be so damaged that forensic analysis is not possible.

Design, Manufacturing, Material, and Installation 34.8% - Just over 1/3 of transformer failures are due to defects that exist when the units are placed in service. These defects make the units vulnerable to the stresses transformers experience while in service.

Aging and Overheating 19.7% - Aging is a broad category that relates primarily to the loss of insulation strength in oil-infused paper insulation. Factors that impact the integrity of insulation strength include the presence of water and oxygen in the oil and excess heat. The key thing to look for are defects in the integrity of the tank and seals and gaskets. Excess heat primarily comes from excessive loading. When the oil and paper are exposed to water and oxygen in combination with the oil and excess heat is present, one can think of the paper as “cooking” in the oil. Just as potatoes become crispy when fried at high temperatures, the paper in transformers becomes brittle when exposed to excess heat. Water and oxygen present promote unfavorable chemical reactions that introduce flammable gasses and compounds that can reduce the insulation strength of the oil and increase the risk of explosions. Heat can also come from external short circuits that cause short-term heating. Short circuits can cause other defects that are discussed next.

External Short Circuits 8.9% - The familiar hum heard coming from a transformer is the result of mechanical forces from current and the flow in the windings that cause the core to flex. The hum is about 120 Hz or twice the electric frequency of 60 Hz as the core flexes once every half cycle. External short circuits on the secondary side of transformers can result in high current flows in the transformer windings. The high currents can cause the core to flex violently and deform and cause changes in the core and tank bracing. Transformers have what is known as damage curves; curves based on current flow and time duration that establish the magnitude and duration of current that a transformer can withstand without damage. The transformer protection should be selected to limit the duration of short circuits such that the time-current magnitude is below the damage curve.

Improper Maintenance 2.7% - Transformer maintenance is primarily concerned with ensuring the level and condition of the oil and ensuring moisture does not enter the tank. For details on transformer maintenance consult IEEE Standard C57.93-2019 - IEEE Guide for Installation and Maintenance of Liquid-Immersed Power Transformers.

Overvoltage and Lightning[4] 1.8% - One of the most common explanations for electrical losses is overvoltage and lightning. Lightning damage can be established by two out of three of the following:

- Meteorological data from services such as STRIKEnet

- Eyewitness testimony

- Physical damage consistent with overvoltage or high current flow

Overvoltages are less likely to damage transformers when surge protection is installed. As a practical matter, overvoltages can sometimes be confirmed or excluded based on damage, or the absence of damage, to other equipment. If it is reported that a transformer - a robust piece of equipment - was damaged by an overvoltage and yet electronics such as telecom equipment, computers, and network equipment is undamaged, it must be questioned how the robust equipment was damaged but the less robust equipment was left undamaged. Conversely, if there was simultaneous damage to a transformer and electronics it is reasonable to investigate the possibility of an overvoltage.

Miscellaneous 7.2% - This group includes the following:

- Abnormal Deterioration 0.9%

- Clamping Pressure 1.8% (Loss of strength of supports/spacing of paper insulation)

- Collateral Damage 0.9% (Damage from other equipment or systems)

- External Pollution 1.8% (Corrosive environment)

- Loss of Cooling 0.9% (Damage to cooling radiators, fans, or oil pumps)

- Other 0.9%

Summary

It would be reasonable to expect an oil-filled transformer to last up to 50 years, however, early failure is not unprecedented, and given a large fleet of transformers it is reasonable to expect failures to occur. The cause of failure may be difficult to determine but is typically related to the condition of the oil and the insulating paper. EDT has engineers available to investigate transformer and other electrical losses.

About the Author

Gary W. Mullis, M.Eng., P.E. is a Consulting Engineer in our Charlotte, North Carolina Office. Mr. Mullis provides consulting in the areas of design and performance of electrical power distribution, transmission, and generation, including fire origin and cause analysis, scope of damage, and repair/replacement economic and technical feasibility analysis. His areas of expertise also include electrical system and equipment performance during fault and unbalanced conditions, as well as analysis of electrical contact accidents, arc flash events, and direct stoke lightning. You may contact him for your forensic engineering needs at gmullis@edtengineers.com or (704) 523-2520.

Learn about how EDT Forensic Engineering & Consulting approaches damage assessment to commercial and industrial and forensic engineering by assigning a file today.

1 The History of the Transformer, The Edison Tech Center, © 2022 accessed at https://edisontechcenter.org/about.html on March 24, 2022

2 Bartley, William H. , Analysis of Transformer Failures, The Hartford Steam Boiler Inspection & Insurance Co.

Hartford, CT USA, International Association of Engineering Insurers 36th Annual Conference – Stockholm, 2003

3 Tenbohlen, S. et. al, Assessment of Power Transformer Reliability, XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

4 Lightning damage may be less prominent in this study due to the lower level of lightning activity in the study countries. Lightning can be expected to be more frequent in areas like Texas and Florida.