Pumps: Putting Fluid to Work

Types of Pumps

Two of the most common types of pumps are centrifugal pumps and positive displacement pumps. Centrifugal pumps provide varying flows at varying pressures. With a centrifugal pump, flow rate and pressure are controlled by valve manipulation, by changing the impeller size (the part of the pump that does the actual moving of the fluid), or by changing the speed of the pump. An example of a centrifugal pump is the hot water circulating pump in a boiler that provides heat to a condo or apartment. This pump circulates water through the boiler and then through the residence to keep the home at whatever temperature the thermostat may be set. Even the propellers on a plane or a boat are types of centrifugal pumps, specifically axial pumps. By moving water or air along the axis of the propellers, the boat or airplane moves.

Positive displacement pumps (PDPs) deliver a fixed volume of fluid with every stroke or rotation of the pump. PDPs come in a wide variety of shapes and sizes. A hand soap dispenser is a good example of a positive displacement pump. Each depression of the dispenser will discharge a fixed volume of hand soap. Another example of a PDP is the fuel pump in a car, which sends a constant flow of fuel to the engine. The human heart, too, is a PDP, with every beat moving a fixed volume of blood.

Pump Maintenance

For those who select, size, or operate pumps and pumping systems, there are considerations of which to be aware when it comes to keeping fluid moving.

Maintenance increases the life span of pumps, and sometimes includes taking the pump apart to repair and replace components. Manufacturers provide recommendations for reassembling and starting up a pump.

Strainers help block debris from entering a piping system. Something as small as a grain of sand entering a PDP will result in damage to pump components. The fuel filter in a vehicle is designed to keep debris out of the fuel, and therefore out of the engine and fuel pump.

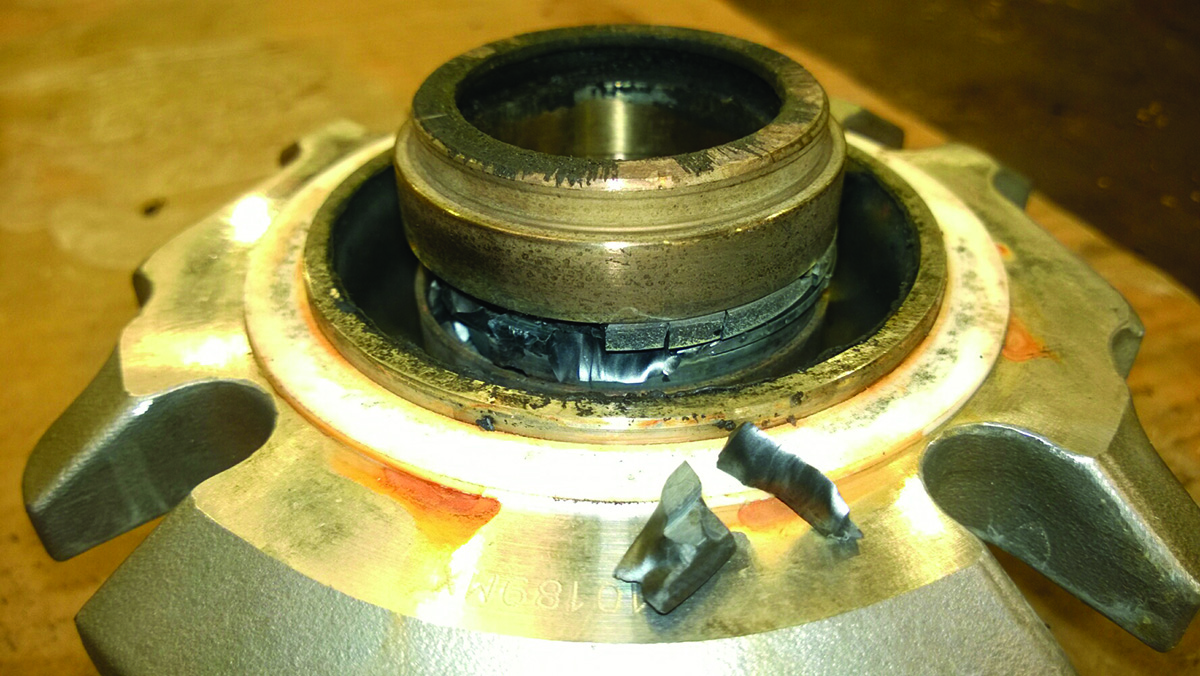

Pumps require seals to keep the fluid being pumped within the pump. In addition, seals also prevent pumped fluid from combining with the oil used to lubricate the pump bearings. Like the pump itself, these seals require maintenance or periodic replacement.

Piping System Design

Improper pipe sizing can starve the pump of liquid, resulting in cavitation. Cavitation occurs when the liquid’s pressure drops so low that the liquid boils, even at low fluid temperatures. In addition to pipe sizing and cavitation concerns, inadequate pipe supports can result in forces (called nozzle loads) that damage the pump. Improper design can also result in the fluid being pumped becoming too hot, leading to damage to pump components, including seals. For example, if a pump is trying to push liquid against a closed valve (called dead-head) and the liquid is stationary, the movement of the pump will result in friction that heats up the liquid. This heat build-up can result in damage to seals and other components.

Pumps work hard to keep fluid moving, but they do need care and attention, whether it’s a municipal water pump or the one we carry around inside of us.