Overhead Door Failure Investigation: How a Simple Installation Mistake Nearly Caused a Serious Warehouse Accident

When you work in facilities that depend on large mechanical systems, even minor installation errors can lead to major safety risks. In one recent case I investigated, a missing bolt on a warehouse overhead door nearly caused a serious injury.

What Happened: A Forklift Operator, a Stuck Door, and a Near Miss

At a refrigerated food warehouse, several overhead doors keep operations running smoothly, separating temperature-controlled areas and allowing trucks to load and unload efficiently.

One morning, staff discovered that the primary refrigerated section’s overhead door had jammed. Following safety procedures, they coned off the area and requested maintenance service.

Later that day, a delivery truck arrived needing to unload perishable goods. In an effort to keep operations moving, someone asked a fellow employee to help push the door open manually. As the employee attempted to lift the door, the entire door derailed from its tracks and came crashing down, striking the employee on the head.

Thankfully, the injury was minor. But given the door’s size and weight, the outcome could have been far worse.

Forensic Investigation: Identifying the True Root Cause

When I arrived on site, my objective was clear: determine why the door failed and how to prevent it from happening again.

Overhead doors of this type are built from multiple panels joined by brackets, with steel cables running vertically from bottom to top. Motors, torsion springs, and cables work in unison to lift and lower the door smoothly.

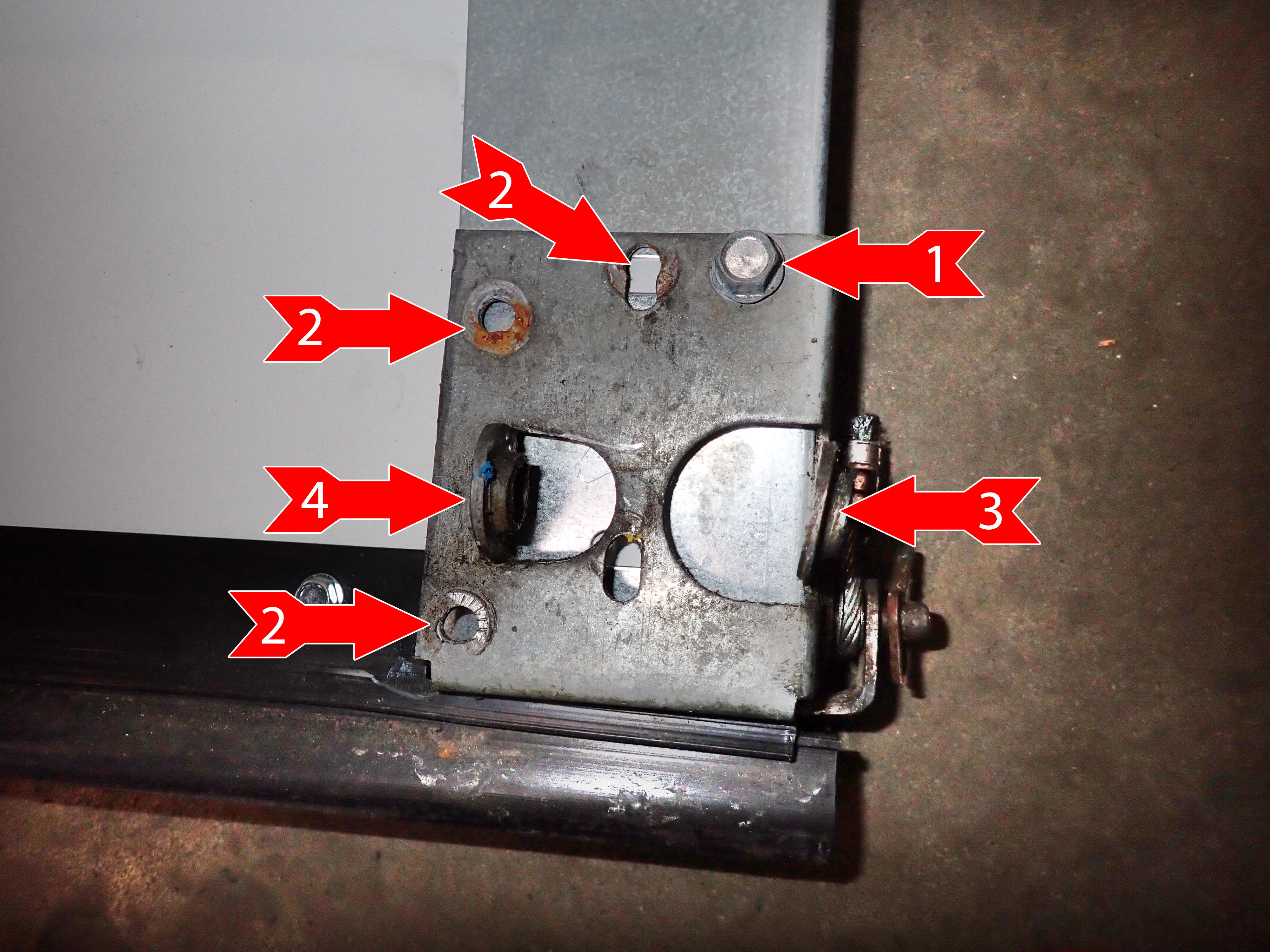

During my inspection, one bracket immediately drew my attention: a bottom corner bracket that was intended to hold the cable assembly in place. I found that the bracket was secured to the door’s bottom panel with only a single bolt. According to the manufacturer’s specifications, the bracket should have had at least three. Further investigation revealed that the door’s bottom panel had been replaced six months prior, which would have required removal of the bottom panel brackets. When the brackets were reinstalled, three bolts were installed in one of the brackets, but only one bolt was installed in the other.

That small oversight set the stage for a dangerous failure.

The Root Cause: Missing Bolts and Misaligned Panels

With only one bolt in place, the bracket could pivot slightly during door operation. That subtle movement caused the door to tilt and bind in its tracks rather than move straight up and down.

Each cycle made the misalignment worse, until the door finally jammed. When force was applied to open it, the door derailed off its tracks and fell.

Key Findings: Lessons for Warehouse Safety and Maintenance

This investigation provided the facility with valuable insights and corrective actions:

- Accurate Root Cause Identification: We determined the exact mechanical issue, allowing for efficient, targeted repairs.

- Minimized Downtime: With the cause identified quickly, the door was repaired and returned to service with minimal operational disruption.

- Clear Documentation for Insurance and Liability: The forensic report provided defensible evidence of the cause and corrective measures.

Preventing Similar Equipment Failures

This case underscores several key principles for anyone managing mechanical or automated systems:

- Follow Manufacturer Specifications Precisely: There’s an engineering reason for every detail and shortcuts often create future hazards.

- Document Repairs Thoroughly: Maintenance records can catch installation errors before they lead to failure.

- Avoid Forcing Stuck Equipment: When mechanical systems jam, forcing them can make the problem worse, or even dangerous.

- Engage Professional Forensic Investigation: When safety or liability is involved, expert analysis delivers clarity and prevention.

Why Professional Investigation Matters

A falling overhead door has the potential to cause life-altering injuries. In this case, prompt investigation prevented further risk and helped the client strengthen their maintenance and safety protocols.

Sometimes, failures stem from complex engineering issues. Other times, as in this case, the culprit is as simple as a missing bolt. Either way, identifying the true cause ensures that corrective action is effective and lasting.

About the Author

John M. Rophael, P.E., is a mechanical consulting engineer at EDT Forensic Engineering and Consulting. He applies more than a decade of experience to evaluate the root cause of mechanical and piping system failures and to provide consultation related to HVAC systems, plumbing, mechanical design, damage assessment, and code interpretation.