High-Risk Stormwater Hydraulics: Why Sewer Surges Aren’t Just Acts of Nature

In my last blog post, I introduced some of the issues with stormwater management systems that can cause or exacerbate rain-driven flooding of homes and businesses (known as pluvial flooding). In this post, we’ll dive deeper into some of the most destructive phenomena that can occur when rain hits urban landscapes. The damages to infrastructure, property, and human life and health from these phenomena go beyond simple water damage.

It's Not Just Water, It’s Energy

Water flow carries, stores, and transfers immense amounts of energy, a fact that has been exploited for millennia in the form of hydro power, from a medieval miller’s wheel in a small stream to modern behemoths like China’s Three Gorges Dam.

Water energy can take one of three forms:

- Kinetic (proportional to the square of the flow velocity)

- Gravitational (proportional to pipe elevation)

- Pressure (proportional to the water pressure and depth)

In sewers, there is a fourth form of energy in the mix:

- Pneumatic (from trapped air that gets compressed – more on that later)

Rapid conversion of one form of energy to the other is often associated with danger and destruction if these transitions are not accommodated. These shifts—if not properly managed through design or maintenance—can potentially lead to structural failures, sewer backups, and severe flooding that impacts both property and public safety.

Why Transitions Matter in Sewer Flow

In addition to the forms of energy present, it’s important to understand the different flow regimes engineers look for during a forensic investigation:

- Open-channel vs. Surcharged

- Subcritical vs. Supercritical

- Inlet-controlled vs. Outlet-controlled

Transitions between these pairs of flow regimes create unstable conditions and transfers of energy, resulting in, you guessed it, the possibility of danger and destruction.

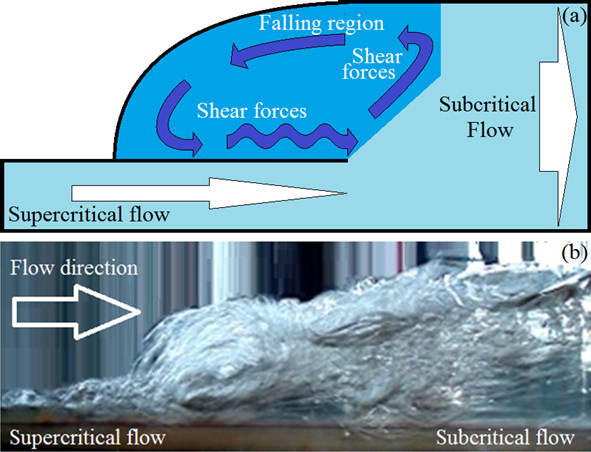

The transition from supercritical to subcritical flow is called a hydraulic jump.

Supercritical flow means the flow velocity is faster than the wave propagation speed. If you stick something into the water surface, ripples will propagate downstream.

Subcritical flow means the flow velocity is slower than the wave propagation speed. If you stick something into the water surface, ripples will propagate upstream.

The same volumetric flow rate can occur in either a subcritical or supercritical manner. Wave propagation speed is proportional to the square root of water depth. Therefore, the increase in depth while flow rate remains constant causes both an increase in wave speed and a decrease in flow velocity.

In supercritical condition, the water is shallower, and the velocity is fast; in subcritical condition, the same amount of flow passes at a slower velocity, making up for the slowness with increased depth and therefore cross-sectional area. As a result, when a flow changes from supercritical to subcritical, energy changes abruptly from kinetic (speed) to potential (depth).

There’s also a third condition called critical flow, where the wave speed equals the flow speed and the gravitational and inertial forces are in perfect balance. But critical flow is highly unstable and it can shift to subcritical or supercritical in response to tiny changes in slope, roughness, channel shape or flow rate.

Because the supercritical or subcritical flows behave so differently at the same flow rate, critical flow is rarely sustained outside of laboratory settings, but instead, manifests as spatial and temporal fluctuations in depth and velocity, such as standing waves, turbulent churn, depth oscillations, or water hammer as the regime shifts back and forth between supercritical and subcritical states.

One common place for hydraulic jumps to form is at an abrupt grade change from steep to mild. These spots can become high-risk areas and should be a focus in any investigation into stormwater backups, sewer overflows, or street-level flooding.

So why does this matter?

In urban stormwater and sewer systems, energy and regime transitions are often points of failure. Hydraulic jumps are easily detectable in flow monitoring data, basic hydraulic modeling, and visual observations, and are therefore one of the first places that a hydraulic forensic engineer looks for clues as to whether a flood control system failed due to lack of maintenance, poor design, or unavoidable external conditions.

From Open-Channel to Pressurized Flow: Where Problems Begin

The transition from open-channel flow (in partially full pipes or uncovered conduits) to surcharged, or pressurized, flow can lead to dangerous conditions – most notably, air entrapment and tunnel-filling bores.

A flow choke, such as an orifice, or a smaller pipe downstream of a larger pipe, causes the upstream pipe to fill once the flow rate exceeds the capacity of the downstream pipe or orifice. This type of flow constriction may be a design flaw or may be intentional if the upstream pipe is designed to function as both conveyance and storage.

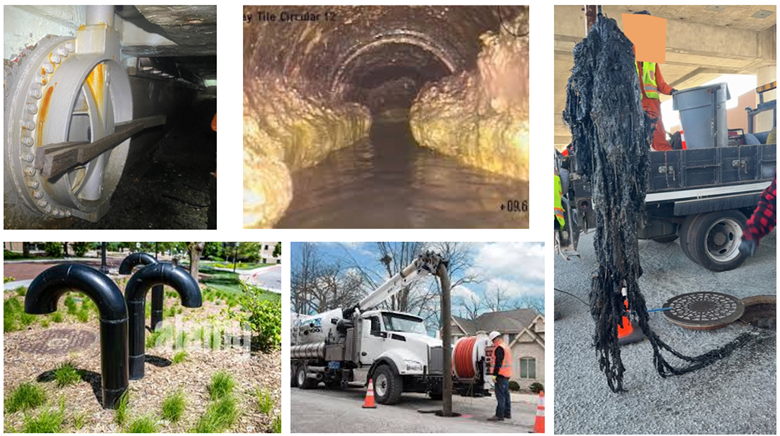

But flow chokes aren’t always designed. Flow constrictions can also be created by maintenance issues, such as:

- a buildup of grease or sediment decreasing the cross-sectional area available

- trash and rags obstructing grates

- or a valve or gate not opening as designed

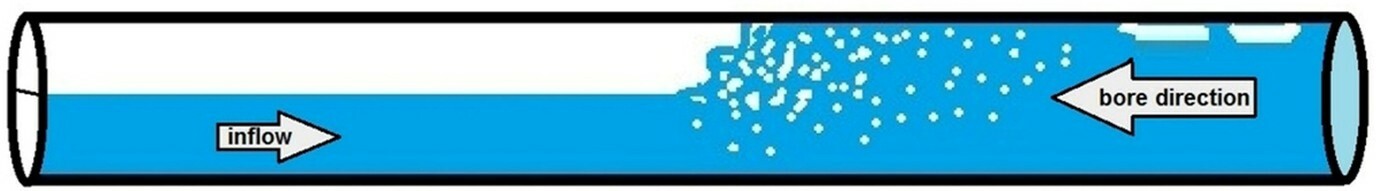

In other cases, the downstream capacity is consumed by rapid inflow, such as from tidal inflow, storm surges, or confluent sewers – creating the same effect as a blockage. When this happens, the pipe fills in reverse – from downstream to upstream – creating a surge called a tunnel-filling bore.

Tunnel-Filling Bores: Hardly Boring

Just as a hydraulic jump is the boundary between subcritical and supercritical flow where velocity is exchanged for depth or pressure and energy changes from kinetic to potential, a tunnel-filling bore is a boundary between unpressurized and pressurized flow and between colliding wave propagation directions. A tunnel-filling bore can be thought of as a backwards-moving hydraulic jump with nowhere to go. In an open channel, a hydraulic jump can propagate upstream as well, but the speed and power of the surge is limited by the height of the channel walls because all the downstream pressure that drives the surge must come from depth, and the channel will jump its downstream banks before it generates sky-high pressure buildup. In an enclosed pipe, there is no limit on the downstream pressures that can build up, until something bursts or fails catastrophically. Therefore, tunnel-filling bores can travel very fast and generate rapid transient pressure spikes upstream of the bore front.

If the energy and pressure is not able to dissipate and a segment of pipe is flow-constricted at both ends, then the surge can be reflected back and forth from one constriction to the other. This is sometimes referred to as “bathtub sloshing”. Imagine the mess that a toddler makes in the bathtub, then apply that to a ten to twenty foot diameter sewer tunnel.

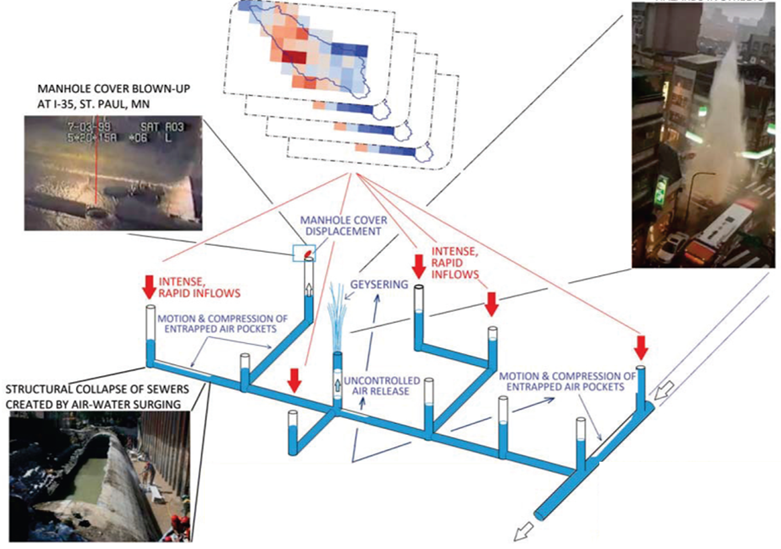

When Air Has Nowhere to Go: The Sewer Geyser Effect

In addition to the damage caused by sudden changes in pressure, these events can also trap air. As the void space between the water surface and the pipe crown disappears, air becomes compressed and stores energy like a pneumatic piston.

Air can be entrapped in sewers through other mechanisms besides tunnel-filling surge fronts. Improperly designed drop shafts, or drop shafts operating above their design capacity, bring air bubbles in with the water, which collect into larger bubbles and eventually air pockets that become compressed between rising water and the crown of the pipe or between surge fronts.

In practice, these two pathways of air entrapment often work in tandem, as the same rapid increases in flow rate that cause tunnel surges, also coincide with large amounts of water entering the system through drop shafts.

If no escape route is provided for the entrapped air, it becomes compressed by the water, generating pneumatic energy storage that can build up to levels sufficient to crack concrete pipes and send 200-lb manhole covers flying, sometimes into buildings or windshields.

When the air does escape, it brings sewer water with it, resulting in release of an air-sewage mixture that rockets to much greater heights than the hydraulic pressure alone could propel it. This is commonly referred to as a “sewer geyser”.

Sewer geysers, flying manhole covers and gaping holes in subsurface infrastructure: these are things nobody wants.

Watch on YouTube: 50-foot tall geyser

The solution is to manage the rate at which sewer flow goes through regime transitions to minimize the amount of energy changing state, and to give air and energy an acceptable place to go.

Some examples of measures that can prevent destructive hydraulic phenomena are:

- Air vents to allow trapped air to escape safely

- Surge chambers to absorb pressure spikes

- Proper pipe sizing to avoid chokes

- Gradual grade change transitions to reduce hydraulic shock

- Influent throttling during fill phase to slow rapid entry

- Confluence design to keep flows moving forward

- Drop structure design to minimize air entrainment

- Sediment / solids management to preserve flow area

- Proper maintenance and repair of gates, valves and pumps

Thank you for joining me on this journey through unstable, rapidly varying sewer flow and its consequences. It’s been a wild ride – and not the kind you find at a waterpark. These systems may be buried underground, but their failures tend to make a splash. When they do, understanding the physics behind the chaos helps us figure out what went wrong – and what could have been done differently.

This is Part 2 of our pluvial-flooding series. Read Part 1 here: https://www.edtengineers.com/blog-post/when-rain-turns-flood

About the Author

Megan E. Abadie, P.E. is a Consulting Engineer at Engineering Design & Testing Corp. (EDT) with a background in hydrology and water resources. Licensed as a Civil Engineer in multiple states including California, Arizona, Colorado, Nevada, Oregon, New Mexico, Texas, Utah, and Washington, Megan specializes in root cause investigations and scope of damage evaluations related to flooding, water intrusion, and infrastructure performance.